eyJzZW9fZGF0YSI6eyJtZXRhX3RpdGxlIjoiQ2hlbWljYWwgUHJvdGVjdGlvbiwgUHJvdGVjdGl2ZSBDb3ZlcmFsbHMifX0=

Categories

Featured Stories

Microgard Protective Coveralls

Ansell Microgard Limited is a leading manufacturer of chemical protective clothing, introducing new ...

Protective Coveralls

| Coverall Standards Explained: | ||

| Type 1 BS EN 943-1 | Gas Tight | Suits which are intrinsically sealed against the environment. |

| TYPE 2 BS EN 943-1 | Non-gas tight | Suits which retain a positive internal pressure to prevent ingress of dusts, liquids or vapours. |

| TYPE 3 BS EN 14605 | Liquid tight |

Suits which can protect against strong and directional jets of a liquid chemical such as spray from a burst pipe under pressure. Requires a barrier fabric and sealed seams.

|

| TYPE 4 BS 1N 14605 | Spray tight |

Suits which can protect against saturation of liquid chemical, where volume of the liquid builds up on the suit forming pools, resulting in rivulets. Requires a barrier fabric and sealed seams.

|

| TYPE 5 BS EN ISO 13982-1 | Dry particle |

Suits for protection against hazardous dusts and dry particles.

|

| TYPE 6 BS EN 13034 | Reduced spray |

Suits for protection against light spray and splashes of liquid chemicals where there is no direction spray or build up of liquid on the suit, but there may be a fine mist of droplets in the atmosphere.

|

| Anti-static EN 1149-5 |

Electrostatic dissipative protective clothing with a surface resistance of maximum 2.5 x 10 exp 9 ohm.

|

|

| Radioactive contamination EN 1073-2 |

Protective clothing against particulate radioactive contamination.

|

|

| Biological EN 14126 |

Protection against biological hazards and infective agents.

|

|

| Limited flame spread protection EN ISO 14116 |

Limited flame spread materials, material assemblies and clothing.

|

|

| Click here to search for the appropriate protection level based on the chemicals in question: Search Chemical Permeation Data |

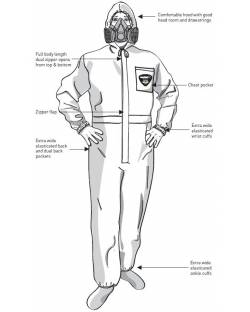

ALPHATEC® 5000 COVERALL REAR ENTRY *Limited Availability*